Flexible electronics applications for example in a printed circuit are made by polyimide or polyester and

More people now demand a flexible printed circuit board and flexible hybrid electronics.

Some of the most common disadvantages of manufacturing flexible electronics are discussed below.

These disadvantages might prove to be a setback for the advancement of the industry, as they could hamper the growth of the applications.

Thus, it is necessary to know about these disadvantages so that you can avoid them.

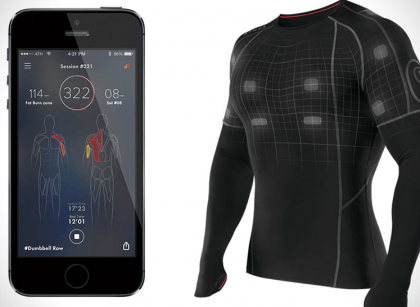

Some of the applications in which these devices are used include computer enclosures, digital imaging tools,

wireless headphones, earbuds, microphones, printers, displays, keyboards, toys, watches, connectors, and scanners.

While using these in all sorts of electronic manufacturing processes, it is important to make sure that the manufacturing of flexible electronics is safe, and that it meets the higher production standards to ensure reliability and quality.

Flaws in the device might give rise to safety hazards, which could result in great losses for the manufacturers.

Therefore, these need to be examined well before manufacturing begins. Once they are checked, the manufacturing process can go on as usual.

When dealing with the manufacturing of flexible electronics, the manufacturers should keep one thing in mind.

You should never try to bend the circuits while making them flexible. This might lead to severe damages, especially in the case of delicate electronic devices.

The use of heat at any stage is also a big disadvantage. It might melt some of the circuits during the manufacturing process, which might give rise to many more disadvantages.

During the manufacturing process, the electronic components of the product have to be perfectly clean and free from dust and debris to avoid faulty results during production.

This is because even the smallest amount of dust or dirt can affect the quality and efficiency of the manufacturing process.

These must also be kept away from water and oil so that they remain dry and unaffected.

If they come in contact with water or oil, there is a big chance that they will get damaged.

If the manufacturing company does not maintain their manufacturing areas, they might face huge losses, as every electronic component has to pass through water or oil at least once during the manufacturing process.

The other major disadvantage of this type of manufacturing is that the devices do not come with any sort of protection.

The producers of these products do not provide any sort of protection against harsh weather conditions.

They are often exposed to extreme temperatures, which may harm them severely.

Therefore, they must ensure that they have adequate protective gear and clothes so that the manufacturing process goes smoothly and is safe for the users.