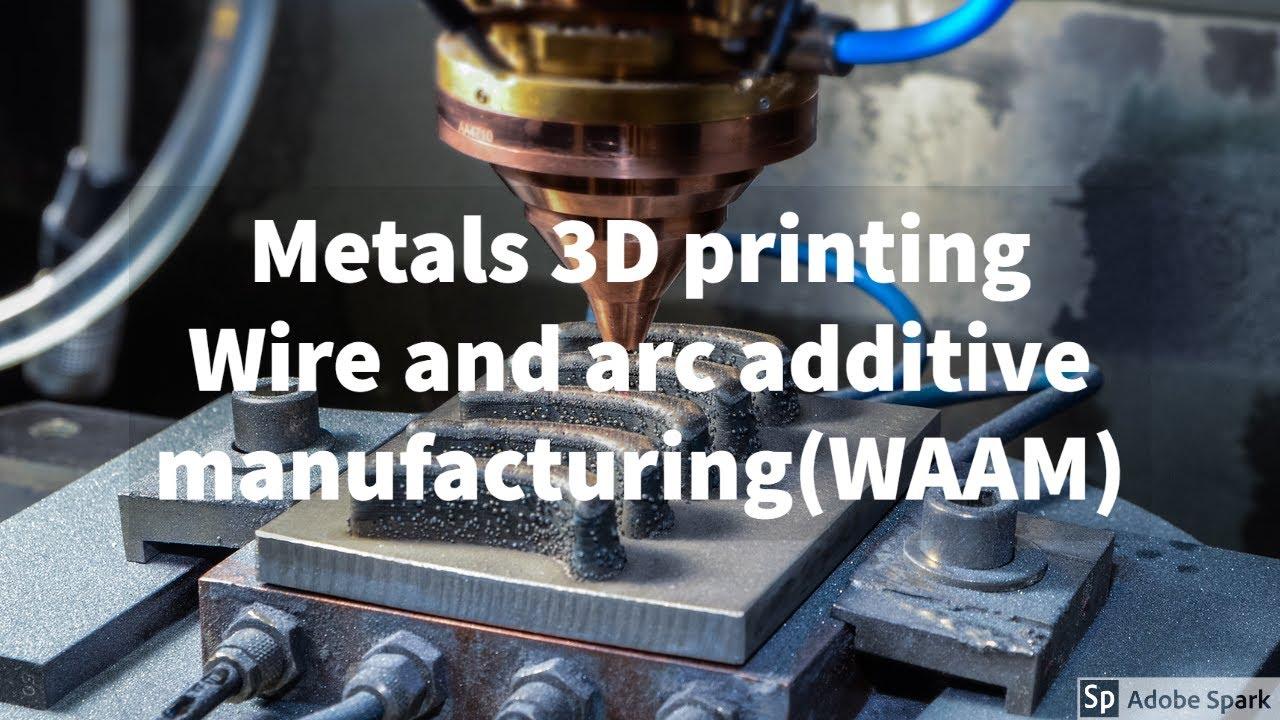

What is Metal 3D Printing?

3D printing is the use of laser-based manufacturing techniques to produce new products with powdered metals.

3D printing is part of additive manufacturing and is now popular in the manufacturing industry, it helps to produce products that can not be possible in the traditional manufacturing process.

Metal 3D Printing Service Areas

Metal 3D printing is now popular in many verticals of manufacturing such as aerospace, automotive, and machines used in medical science.

It is preferred because it allows complex metal parts to be printed at a relatively low price compared to traditional metalworking manufacturing techniques such as machining, milling, or vacuum casting.

With the various 3D metal printers on the market now, there are more achievements in 3D printing.

3D printing companies now have the choice to choose between powder coating, metal separation, and hybrid systems.

Applications of Metal 3D Printing

Metal 3D printing is mainly used today in the manufacturing industry to make tool components or finished parts.

In the aerospace industry, it can be used to produce aircraft components or rocket engines.

In the automotive industry, there are molds for the mass injection of thousands of components that can be produced.

Also in medicine, it is a matter of measuring implants, especially in the dental field.

Metal additive manufacturing can even be used in the marine sector to construct boat propellers.

The fields of application are broad and 3D metal printing will certainly open up even more areas and applications in the future.

3D Printing Processes

There are now different processes for 3D printing with metal, more than what we have at the inception of this technology.

These processes enable a manufacturer to produce the specific parts that are needed to be printed.

The powder bed-based melting process, which was first introduced in the 1970s, is subject to a relatively simple principle – an energy source that sinters or melts a metal powder to make the finished product, layer by layer.

The best-known technology based on this principle is undoubtedly Direct Metal Laser Sintering (DMLS), which was patented by ERD and EOS in the 1990s.

We can differentiate between the method developed by the Irepa laser and the Direct Additive Laser Construction (CLAD).

The powdered metal is projected from the nozzle and fused at its outlet via a laser beam to form a kind of welding bead.

In another dimension from the powder bed-based melting, this method can be used to print directly onto a part.

In the 1990s, CIRTES developed a new hybrid method, the so-called Stratoconception, which combines additive processing and additive manufacturing.

Cold spraying is another process also known as the cold cutting process.

The aim is to connect the metal powders by projecting them cold onto a carrier. The projection is ensured with helium.

It is a 3D metal printing process that is used rarely today compared to others because the gas that’s used is relatively expensive.

Some manufacturers have developed their own patented technologies that stand out from the large providers already mentioned.

We think of the magnetic metal handling by magnetism developed by Vader Systems or of the technology of metal injection molding, inspired by the French Pollen AM.

Metals that are used in Additive Manufacturing

In additive manufacturing, one of the most common metals we find useful is aluminum, mostly in the form of an alloy that offers both lightness and strength.

It is mainly used for parts where weight is important, such as in aerospace and automobiles.

Steel is also a popular material, especially in industry. It has good mechanical properties and a beautiful surface.

It is the most common material used in metal additive manufacturing.

In addition, there are materials such as gallium, and cobalt-chromium, which are particularly suitable for medical applications, and titanium, which is very resistant to corrosion and has a high level of biocompatibility for medical applications.

Precious metals are mainly used in jewelry. Despite the high cost, we find gold, silver, and bronze very useful in making all kinds of jewelry.